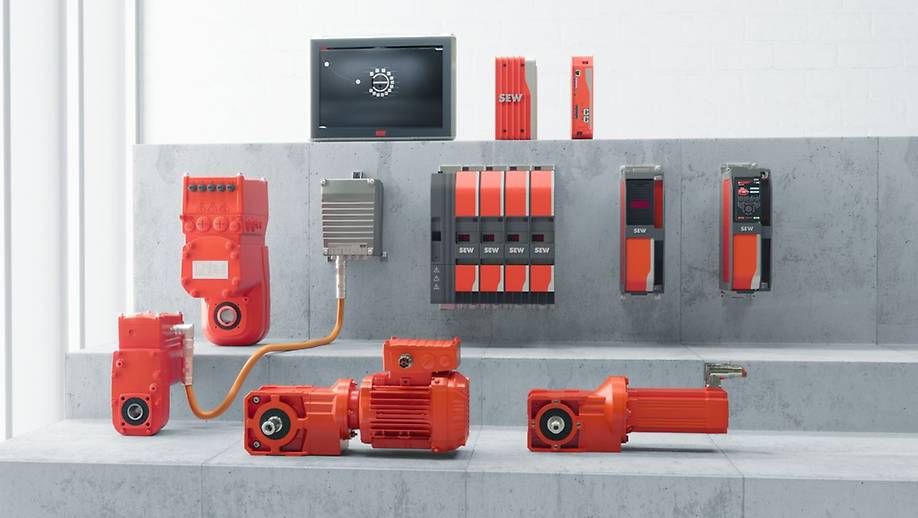

Flexible modularity is one of the most important trends in the engineering business. The open range of software modules from our MOVI-C® modular automation system provides the ideal starting point for implementing modular machine concepts for filling and sealing machines. A typical example is the automation of a cup-filling machine.

Modular application modules for greater flexibility

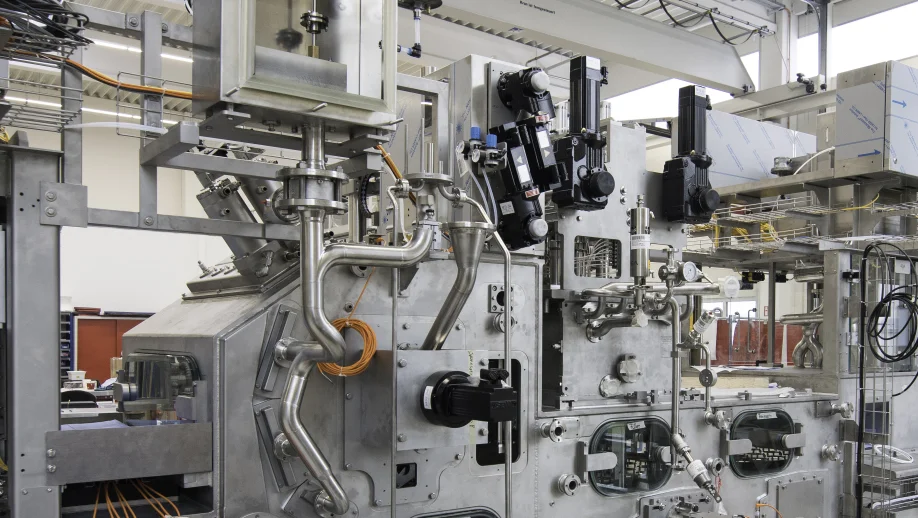

The individual demands of consumers are constantly growing and so are those of food producers. This means manufacturers of packaging and filling machines are being presented with new challenges time and time again to develop their machines in a modular way for automation. At the same time, the demand is growing for technologies that are as reliable as they are available, as well as being innovative and offering scope for future expansion. And, if possible, from a single source.

The innovative operating concept from SEW‑EURODRIVE makes simple and intuitive machine operation possible – even via smartphone and tablet.

SEW-EURODRIVE is exactly the right partner for this. With our MAXOLUTION® automation solutions, we rely on object-oriented programming and offer ready-to-use software modules for the respective applications with MOVIKIT®. With the appropriate selection of typical technology functions and simple and time-saving parameterization, the modules and applications of a horizontal cup-filling machine can be set in motion quickly, efficiently and in a perfectly synchronized manner.