On reaching the end of a packaging line, most products still need to be placed on pallets before going to the logistics section. Nowadays, the palletizing systems required for this process need to be increasingly versatile and highly automated. New robot technologies are enhancing or replacing traditional systems. Our MOVI‑C® modular automation system provides ready-to-use software modules and the necessary flexibility for axis control.

Modular solutions for all kinds of palletizing and depalletizing

Four main types of palletizing robot are used – articulated arm robots, layer palletizers, linear robots and gantry palletizers. Pack size, pack weight and the nature of the packaging being utilized are key factors when it comes to machine functions and movements. The software used needs to be just as modular as today's new lines and fully automated palletizing systems.

By teaming up with SEW‑EURODRIVE, we've managed to establish a strong and long-lasting partnership that gives rise to a whole host of innovative ideas. The resulting solutions ensure we are able to maintain absolute safety and reliability, while also achieving outstanding levels of performance.

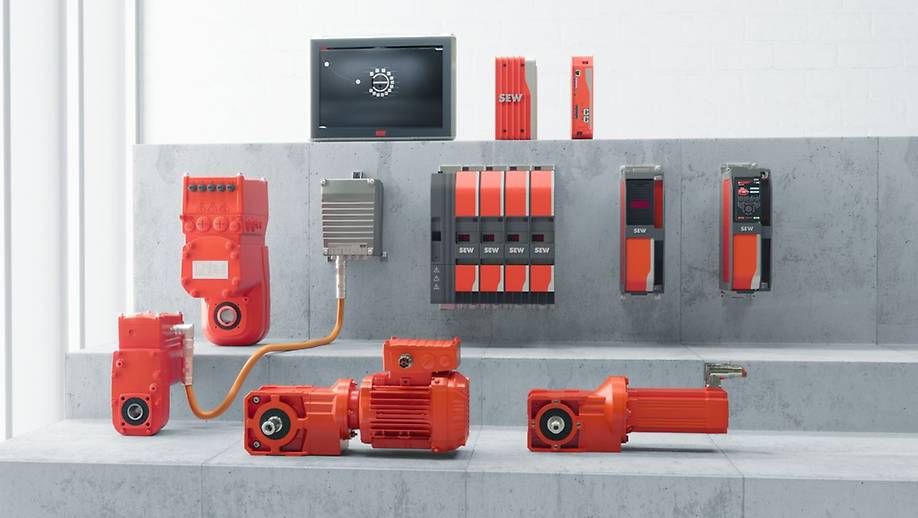

Our MOVI‑C® modular automation system provides this modularity, which ensures maximum flexibility and simplicity for programmers. In conjunction with our wide-ranging software solutions, intelligent axis control ensures speed and reliability plus gentle container handling and excellent stacking quality.

Regardless of the robotics option / robot kinematics used, our MOVIKIT® Robotics software module always has exactly the right solution, with extremely easy parameterization replacing complex programming.