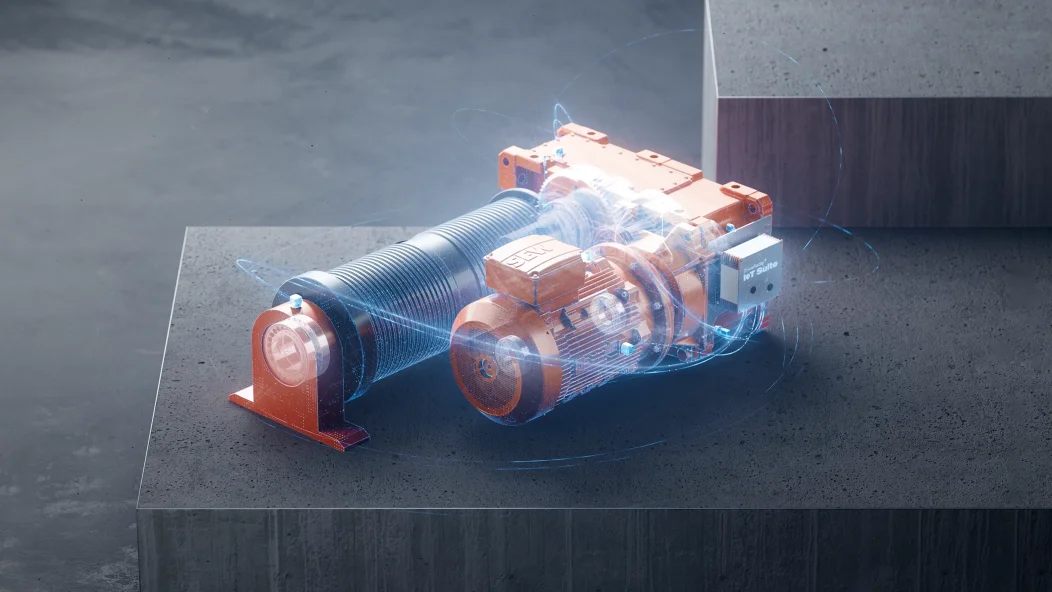

The app supports everything from installation and startup to maintenance and fault diagnostics. Technical data and documentation are provided in a product-specific manner and as step-by-step instructions.

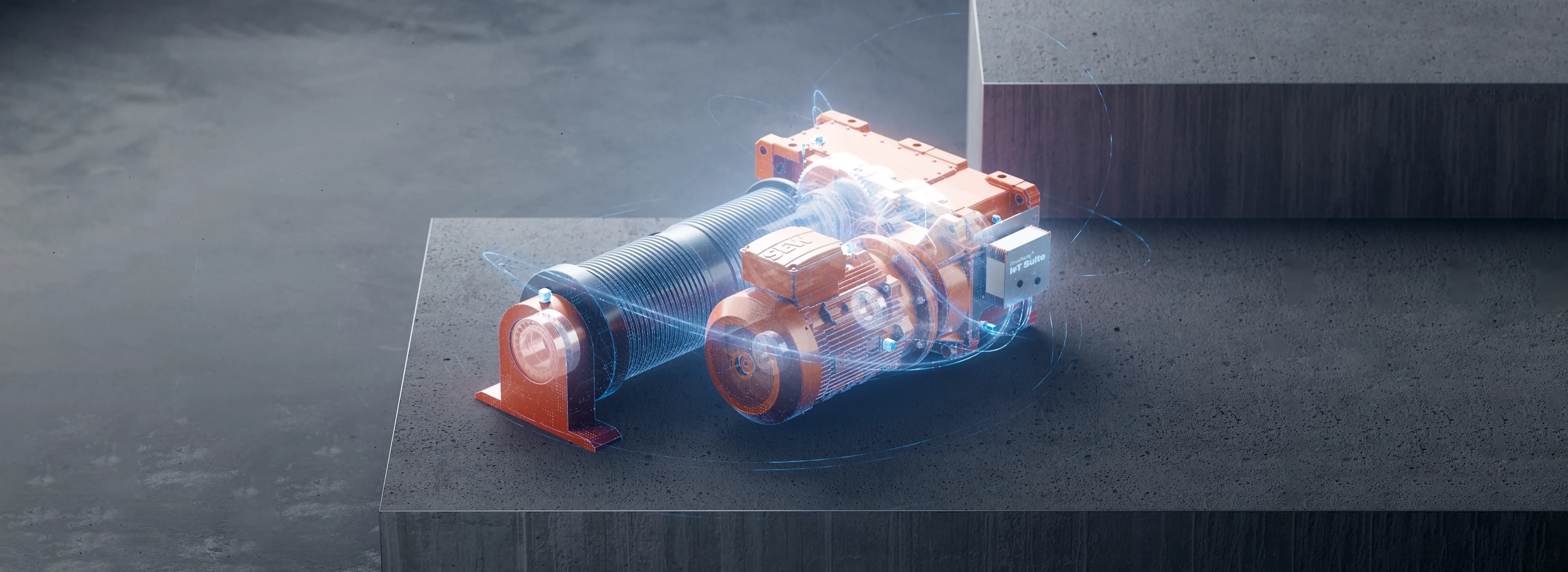

All applications monitored with DriveRadar for industrial gear units are clearly displayed and all current measured values and associated limit values are displayed. In the event of status changes, the app immediately informs you with notification and initial recommendations for troubleshooting.

In summary:

- App for mobile devices included

- Automatic notification of errors and warnings