Multidimensional material transportation and material processing – in machine automation, handling the products is an important step in the process chain. Loading and unloading directly affect the cycle time of the machine. The motion profile must therefore be fast, precise and gentle to the product and the machinery, too.

Path control, handling and kinematics

– how to start up robots intuitively

It’s hard to imagine automation engineering – especially machine automation – without robots anymore. We offer a comprehensive portfolio for implementing your application-specific robotics solution.

Click on the dots here to find out more:

- Run on the controller

- Operate the drives

- Are particularly easy to startup, precise and reliable

- Comprehensive portfolio for complete automation

- From motion controllers to high-performance controllers

- In different designs

- In a DC link network with optimum energy flow

- Flexible in every respect

- With MOVIDRIVE® modular and Power and Energy Solutions

For years, our motors and gear units have been famous for their high quality and fatigue strength.

Our modular system has something to offer when it comes to robots, too.

- Displays with integrated controllers and keypads

- WebVisu for use with external devices

- Comprehensive templates

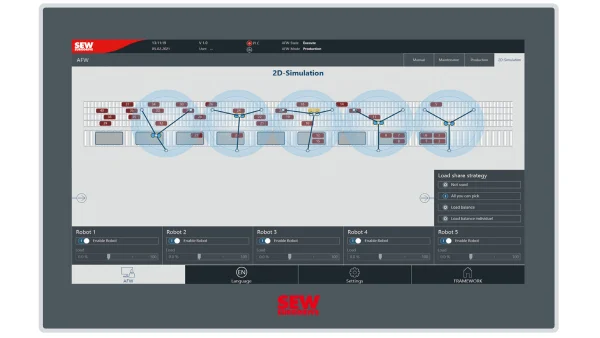

The RobotMonitor is the interface between the robot and the human. This puts the operator firmly in control.

Comprehensive services along the entire life cycle of a system complement our portfolio.

- The drive mechanics turn electrical power into dynamic movement.

- With the CM3C.. series synchronous servomotors and the PxG® planetary servo gear units, you have the ideal components for doing just that.

Dynamic, precise and gentle

Typical applications for our robotic solutions include pick and place, palletizing and stacking, transportation and transfer and packaging. Our robotic solutions are also ideally suited to processes for finishing products, such as decorating food and on-the-fly processing. Alongside the highest demands on dynamics, products should also be handled as gently as possible. At the same time, the process is only stable if material can be processed with a high level of accuracy in a reproducible way.

With MOVIKIT® Robotics, for example, we have developed suitable software modules for areas of application such as these. Furthermore, on the hardware side, our parallel arm kinematics kit is available to make it possible to implement systems with such complex and rapid motion sequences. Together, they form the ideal solutions platform with which you can implement path movements as simply and efficiently as when working with a single axis.

MOVIKIT® Robotics and the add-ons

No complex programming language – directly at the machine – entirely intuitive

The MOVIKIT® Robotics software module is the basic software for controlling a robot. It provides a wide range of parameterizable kinematic models. The comprehensive functionality included in the basic software can be expanded with numerous add-on programmable modules, offering specialized functions.

Dr. Markus Müller, Application Software MOVIKIT® Robotics

What we call standard, others call customized

“No matter whether you are planning to use SCARA, gantry, articulated arm or delta robotics, for example, in your application, we will use our standard product portfolio to design customized solutions for a whole range of robot kinematic models. These innovative drive and automation solutions can be found in almost every sector and application – worldwide – from the packaging industry, automotive manufacture, material production and the metal industry to the food and beverage processing industry.”